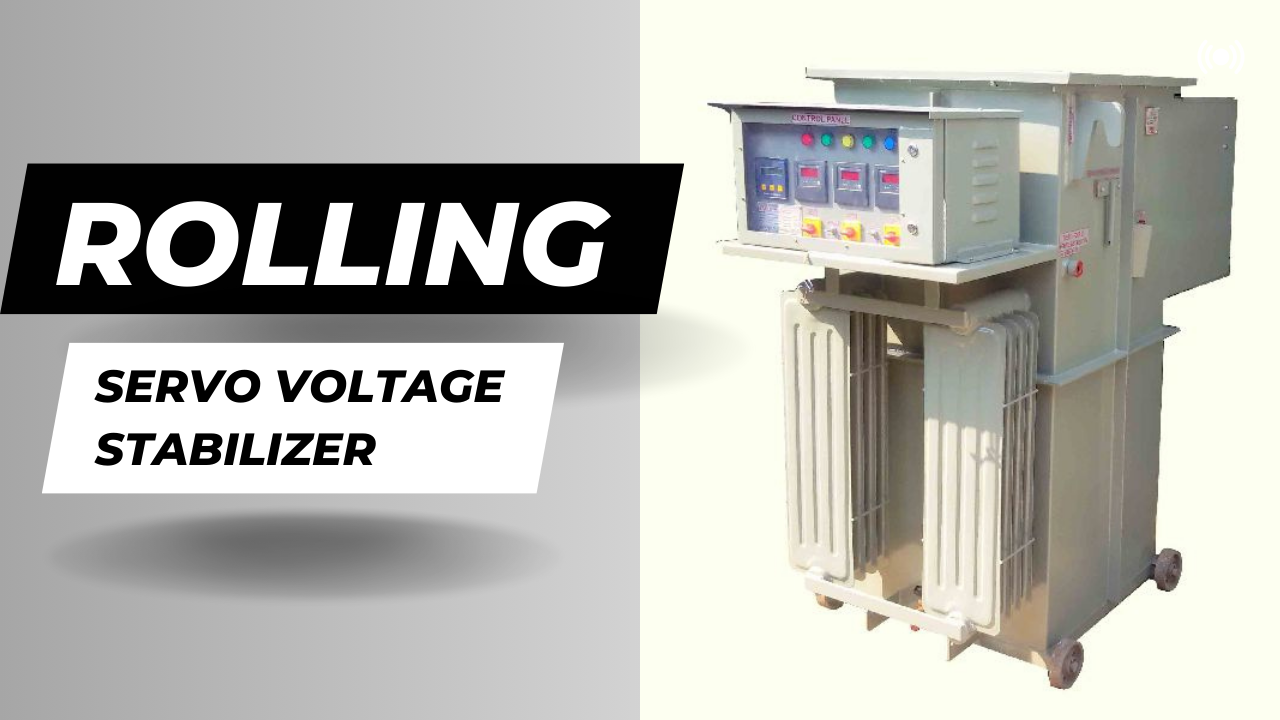

What is a Rolling Servo Voltage Stabilizer?

A rolling servo voltage stabilizer is a device that maintains a constant voltage level in electrical systems despite fluctuations in input voltage. It continuously adjusts the output voltage using a servo mechanism to counter variations in input voltage, ensuring stable power supply to connected equipment.

Types of rolling servo voltage stabilizer?

- Single-phase Rolling Servo Voltage Stabilizer: Designed for single-phase electrical systems, typically used in residential or small commercial settings.

- Three-phase Rolling Servo Voltage Stabilizer: Suited for three-phase electrical systems, commonly found in industrial and commercial applications where higher power loads are present.

- Indoor Rolling Servo Voltage Stabilizer: Designed for indoor use, these stabilizers are compact and suitable for installation in buildings, offices, and residential spaces.

- Outdoor Rolling Servo Voltage Stabilizer: Built to withstand outdoor conditions, these stabilizers are weatherproof and can be installed in outdoor electrical setups or in areas where space is limited indoors.

- Oil-Cooled Rolling Servo Voltage Stabilizer: These stabilizers use oil as a coolant for the transformer and other components, offering efficient heat dissipation and enhanced performance, often used in heavy-duty industrial applications.

- Air-Cooled Rolling Servo Voltage Stabilizer: Instead of oil, these stabilizers use air as a coolant, making them more suitable for applications where oil-based systems are not preferred, such as clean room environments.

- Automatic Rolling Servo Voltage Stabilizer: Equipped with automatic voltage correction capabilities, these stabilizers can adjust the output voltage without manual intervention, providing hassle-free operation.

Features of linear servo voltage stabilizer?

Rolling servo voltage stabilizers come with various features to ensure efficient voltage regulation and reliable performance. Some common features include:

- Wide Input Voltage Range: Capable of handling a wide range of input voltages to stabilize the output voltage within the desired range.

- High Accuracy: Precise voltage regulation to ensure the output voltage remains constant, typically within a tight tolerance range.

- Fast Response Time: Quick response to input voltage fluctuations to maintain stable output voltage, ensuring continuous operation of connected equipment.

- Overload Protection: Safeguards against excessive current flow or power surges, preventing damage to both the stabilizer and the connected devices.

- Short Circuit Protection: Automatically disconnects the output in case of a short circuit condition, protecting the stabilizer and connected equipment from damage.

- Temperature Protection: Monitors internal temperature and activates cooling mechanisms or shuts down operation if the temperature exceeds safe limits.

- Digital Display: Provides real-time monitoring of input and output voltage levels, allowing users to track performance and diagnose issues.

- Remote Monitoring and Control: Some models offer remote monitoring and control capabilities, allowing users to adjust settings and receive alerts remotely.

- Energy Efficiency: Designed for optimal energy efficiency, reducing power consumption and operating costs over the long term.

- Compact Design: Space-saving and compact design for easy installation in various environments, including indoor and outdoor applications.

- Noiseless Operation: Operates quietly without generating excessive noise, suitable for use in noise-sensitive environments such as offices or residential areas.

- Long Lifespan: Constructed with high-quality components and durable materials to ensure a long operational lifespan with minimal maintenance requirements.

Difference between Linear Stabilizer and Rolling Stabilizer?

The terms “Linear Stabilizer” and “Rolling Stabilizer” aren’t standard in the context of voltage stabilizers or general stabilization technology. However, if we’re discussing stabilization in general terms or adapting the names creatively, here are possible interpretations and differences based on similar terminologies:

Linear Stabilizer

This could refer to a device or technology that stabilizes voltage, motion, or other variables in a linear fashion, which means it may directly adjust to the input without requiring complex processing or feedback loops. In the context of voltage stabilizers, a “Linear Stabilizer” might be akin to a linear voltage regulator.

Linear Voltage Regulator:

- Mechanism: Maintains a constant output voltage despite changes in the input voltage or load conditions by dissipating excess electrical energy as heat.

- Efficiency: Typically less efficient than switched regulators, especially when the difference between input voltage and output voltage is large, because excess voltage is dropped as heat.

- Application: Commonly used where low output noise and ripple are critical, such as in sensitive audio or measurement equipment.

Rolling Stabilizer

This term isn’t standard but could creatively describe a stabilizer that adjusts its output through a rolling mechanism, perhaps analogous to rolling averages or incremental adjustments seen in some complex systems. In a broader mechanical context, this might imply a device that uses rolling or rotational components to achieve stabilization.

However, if interpreting it within the framework of common stabilizing technology, one might consider something akin to a “Rotary Stabilizer”:

Rotary Stabilizer (if we consider rotary akin to “rolling”):

- Mechanism: Uses a motor-generator set where the motor adjusts to speed variations, and the generator produces a stable output voltage. This type uses mechanical inertia and electromagnetic effects for stabilization.

- Efficiency: Can be very efficient in stabilizing against large and fast voltage fluctuations and typically has high reliability due to fewer electronic parts.

- Application: Often used in industrial applications where large machinery requires consistent voltage despite heavy and fluctuating loads.

Indian Servo Controls Make a Stabilizer Fully Details

| Customize |

Copper Wound |

| Capacity | 30-500 KVA |

| Life | 15-20 Year |

| Output | 400 |

| Efficiency | 98.99% |

| Warranty | 5 Year |

| Delivery | 15-25 Days |

| Range | 360-460

340-460 340-480 320-480 300-480 280-480 |